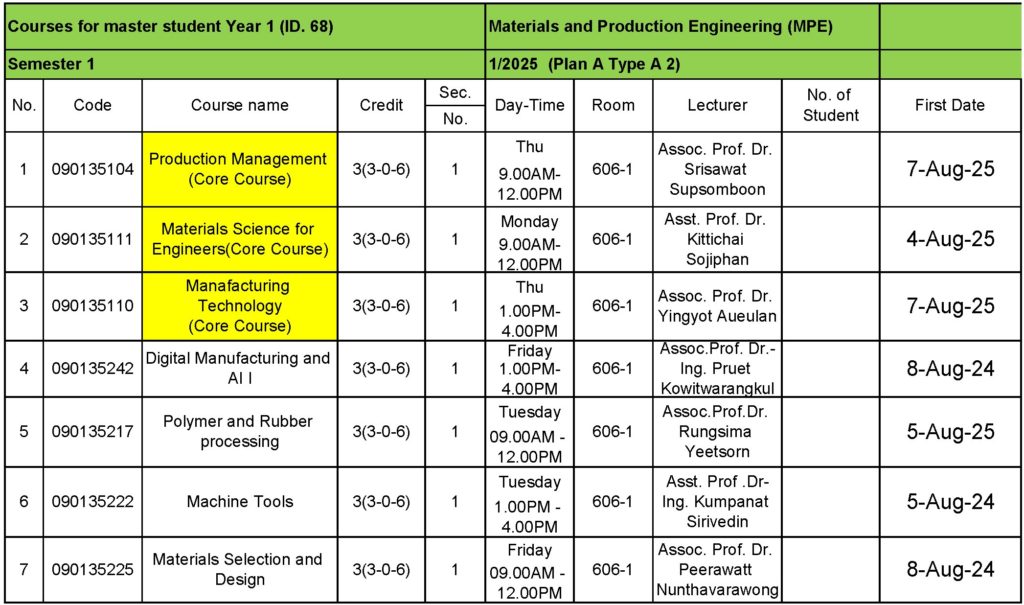

| Code | Courses | Credits(Lecture/Practice/Self-study Hours) |

| 090135104 | Production Management (Core Course) | 3(3-0-6) |

| Production management. Using operation to complete. Develop process strategy. Analyzing processes. Managing Quality. Total quality control. Planning capacity. Managing process constraints. Designing Lean system. Managing inventories. Designing effective supply chains. Locating Facility. Planning and scheduling operations. Managing demand. | |

| 090135225 | Materials Selection and Design | 3(3-0-6) |

| Materials selection, especially together with other components fabricated by other materials. Ashby chart. Consideration criteria for materials selection: price, strength, density, thermal conductivity, thermal expansion, electrical conductivity, corrosion resistance, galvanic series, ability to recycle, alternative materials, green materials. | |

| 090135110 | Manufacturing Technology (Core Course) | 3(3-0-6) |

| Mechanical properties of materials, Techniques used to determine those properties as well as basic polymer engineering rheological properties The second part will overview a principle of manufacturing technologies, including forming (sheet and bulk) processes, casting process and powder metallurgy process as well as polymer processing Some specific in forming technologies such as sheet and bulk forming using case studies to the emphasis in the ongoing research in those processes. | |

| 90135242 | Digital Manufacturing and AI I | 3(3-0-6) |

| Principles of CAD/CAM/CAE; computer modeling and simulation techniques finite volume and finite element methods; MATLAB coding; fundamentals of numerical heat transfer; introduction to Computational Fluid Dynamics (CFD); case studies in materials and production engineering; additive manufacturing technologies; automation systems in manufacturing; smart factory concepts; application of artificial intelligence (AI) techniques in manufacturing. | |

| 090135217 | Polymer and Rubber processing | 3(3-0-6) |

| Principle and application of polymer processing. Practical detail of conventional process such as extrusion, injection, blow molding, compression, thermo forming, and rotational molding. | |

| 090135222 | Machine Tools | 3(3-0-6) |

| Introduction to various machine tools. Design of machine components. Optimization of machine components. Evaluation of machine tools. Measuring instruments for machine tools evaluation, Automation technology for machine tools. Control systems, Numerical control. Communication technology and command control, Integrated manufacturing systems, Machine tool monitoring and diagnosis, Artificial intelligence in machine tool monitoring. | |

| 90135111 | Materials Science for Engineers (Core Course) | 3(3-0-6) |

| Atomic structure and interatomic bonding, structure of crystalline solids, imperfections in solids, diffusion; types of materials, metals, polymers, ceramics, composites; phase diagrams, phase transformations, heat treatment; polymer molecular structure, crystallization, melting and glass transition, polymerization; mechanical behavior, deformation and strengthening mechanisms; brittle and ductile fracture, types of failure, corrosion and degradation of materials; electrical, thermal, magnetic, and optical properties of materials; new materials development for industrial applications; use of artificial intelligence in materials science problems. | |